Biomechanical Hoof Tester

RSTL OBST Standard Operating Procedure – 2023

The Orono Biomechanical Hoof Tester is a system that has been developed to make it possible to load the track at the rate and loads that are applied by a horse at a gallop (Peterson, et. al., 2008). This system mimics the point at which the fore limb contacts the track and the weight of the horse is transferred to the hoof. This is the period of the gait during which both the highest vertical loads and the highest shear loads are applied to the soil. The device that has been developed is a two axis drop tower type of apparatus which impacts a synthetic hoof at an angle to the soil surface. Two non-orthogonal axes of motion allow acceleration due to the sliding of the hoof in contact to be measured as well as vertical loads and vertical acceleration. From Figure 3 the two axes can be seen as a long set of rails and a shorter linear bearing apparatus which is attached to the hoof. With gravity acting on the first axis, the long rails on which the hoof and instrumentation slides, the force is generated by accelerating this mass down the rails. The total mass of the portion of the system that drops on the long rails is 30 kg which provides energy at impact of approximately 540 J.

This impact energy accounts for the energy of the hoof impacting the surface as well as the partial weight of the animal and associated musculature. A second set of shorter linear rails moves down as a part of the mass attached to the slide. This second axis is preloaded by a gas spring and only moves once the hoof is in contact with the soil. The difference in the angle between the first and second axes, 5 degrees from the long rail angle, forces the hoof to slide forward towards the toe as it impacts the soil and the second preloaded axis is compressed. The angle at which the hoof impacts the soil is adjusted to match the published biomechanical data for initial impact of the hoof. A total of five data channels are recorded during the testing. Attached to a stiff mass above the hoof is a three axis 100 g accelerometer. Load is transferred into the gas spring from the hoof mass using a dynamic load cell with a 0 Hz (DC) to 36 kHz bandwidth. Redundant data from the acceleration and the position measurement is used to estimate the penetration into the soil and to verify the velocity of the hoof at impact. The angle of the hoof with respect to the soil is adjusted to 7 degrees from the vertical to match treadmill data from horses at a gallop. Some data is currently available from the Biomechanical Hoof Tester; however it remains to be shown that the dynamic response is correlated with the response of the horse at a gallop.

The biomechanical hoof tester replicates the speed and impact of one of the most critical phases of the gait for risk to the horse. While the two measured characteristics, shear and impact force, are expected to be related to performance of the horse, it is even more likely that these parameters measured with the full load and speed of the hoof landing represent the risk to the horse of catastrophic injury to the forelimb. The system has also been adapated to match the biomechanics of the leading forelimb of a horse landing during a show jumping event (Hernlund et. al., 2013). Two systems are now in use in the United States, one in the United Kingdom and another machine based in Sweden.

- Peterson, M.L., McIlwraith, C.W., and Reiser, R.F. (2008) “Development of a system for the in-situ characterization of thoroughbred horse racing track surfaces.” Biosystems Engineering 101: 260-269.

- Elin Hernlund, Agneta Egenvall, Michael L. Peterson, Christie A. Mahaffey, Lars Roepstorff, “Hoof accelerations at hoof-surface impact for stride types and functional limb types relevant to show jumping horses”, The Veterinary Journal, Vol. 198, Suppl 1, December 2013, Pages e27–e32

Ground Penetrating Radar

RSTL GPR Standard Operating Procedure – 2023

Ground Penetrating Radar allows maintenance personnel to see inside the racetrack to identify possible problems.

In 2005-06 the Oak Tree Foundation, Southern California Equine Foundation and Dolly Green Foundation funded research into the imaging of the base on racing surfaces. Design of a system tailored to racing surfaces was performed by Geophysical Survey Systems, one of the world’s leading companies providing ground penetrating radar equipment based in Nashua, New Hampshire.

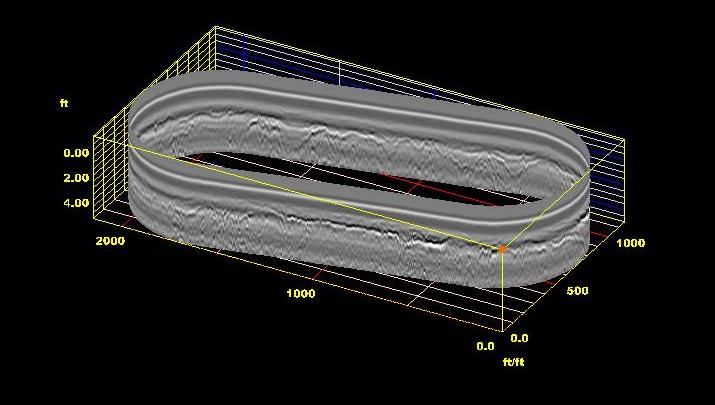

The principles of ground penetrating radar (GPR) are quite straightforward making use of electromagnetic waves to see inside the surface of the racetrack, much like ultrasound, X-ray or other imaging methods (https://www.youtube.com/user/GPRbyGSSI). The resulting data is then synchronized with simultaneous GPS data to create a map of the interior of the racing surfaces.

Among the information that can be obtained from the GPR data is drainage, showing wet or dry areas of a turf or dirt track. Areas of inconsistent composition where either synthetic or dirt materials may have become segregated are also evident in many cases where, for example, clay is lost due to runoff in a dirt surface or fiber accumulates in the synthetic racing surface. Or, most commonly where there is an area with an inconsistent amount of material over the base or damage to the base from water, maintenance or even frost damage. All of this, like any imaging method, requires careful data interpretation.

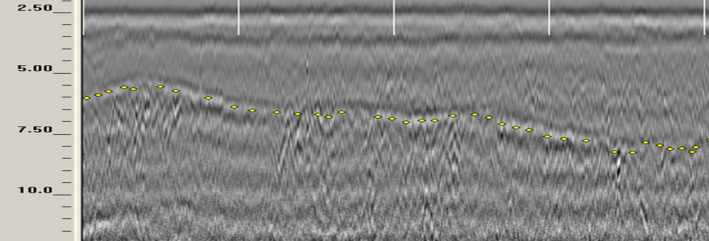

Simple cross-sectional views of the racetrack can be used to identify areas whereas in the example the amount of cushion over the hardpan is inadequate.

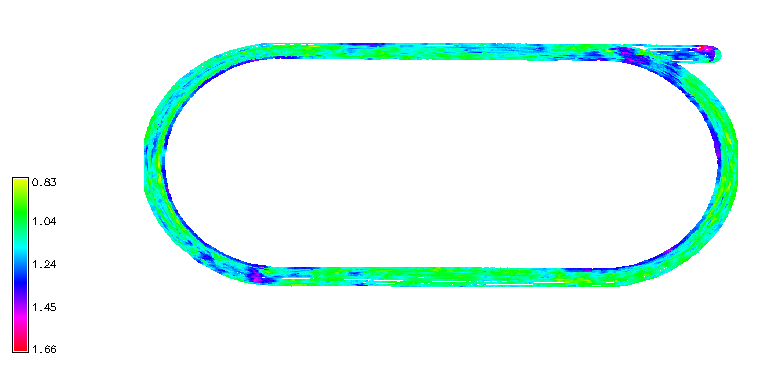

The way that the data is usually presented for the maintenance personnel at the racetrack is through a color-coded map. Often this type of map is useful for not only identifying issues but by comparing the map to locations of various activities on the track a longer-term solution is possible. Most common is inconsistent cushion depth along the rail caused by issues with grading or harrow set up. Water flow across or through the surface can impact consistency of dirt or turf tracks. If the track is always maintained in one direction, then a low spot will develop on the entrance to the turn with the material deposited on the exit from the turn, just simply a consequence of the inertia of the harrow. Finally, traffic from horses, maintenance equipment, and other events can result in areas on the track which are less consistent.

The goal with all of this testing is to provide immediate feedback for the maintenance team at the racetrack. Often these issues can be resolved while the test team is still on site and the track will be retested to make sure that the solution worked. Like all of the work of Biologically Applied Engineering, we are focused on making measurements to support track maintenance personnel to ensure that the most consistent possible surface is provided for racing and training.